Thermal Imaging Services in Forster NSW

David Anderson Electrical is your number one choice for thermal imaging testing (also known as “Infrared Thermography”) in the Forster Tuncurry and Port Macquarie region. With many years of experience in the field and a commitment to excellence, we have built a reputation for providing top-notch service to our valued clients.

Fluke Thermal Imaging Equipment

We understand the importance of accurate and reliable thermal imaging testing in Forster households, and that’s why we use the latest Fluke Thermal Imaging Equipment. This state-of-the-art technology allows us to detect electrical issues that are invisible to the naked eye, such as overheating components, loose connections and potential fire hazards. Our advanced thermal imaging equipment ensures that we can identify and address these problems quickly, preventing costly downtime and ensuring the safety and efficiency of your electrical systems.

We are dedicated to mastering the art of thermal imaging testing in Port Macquarie. Our expertise, combined with our cutting-edge equipment, makes us the go-to professionals for all your thermography needs. Whether you are a homeowner concerned about electrical safety or a business looking to maintain your infrastructure, we have the skills and technology to deliver exceptional results.

Choose David Anderson Electrical for your thermal imaging testing needs and experience the difference that expertise and advanced technology can make. Your safety and satisfaction are our top priorities.

What is Thermal Imaging?

Thermal imaging testing, also known as infrared thermography, involves using thermal cameras to capture and analyze the heat emitted by objects. This method provides a visual representation of temperature variations, which can be incredibly useful in various fields. Here’s a brief overview of its applications and benefits:

Thermal Imaging Applications:

- Building Inspections:

- Energy Efficiency: Identifying heat loss or gain in buildings, helping to improve insulation and reduce energy costs.

- Moisture Detection: Finding leaks and water damage by detecting temperature changes caused by moisture.

- Electrical Inspections:

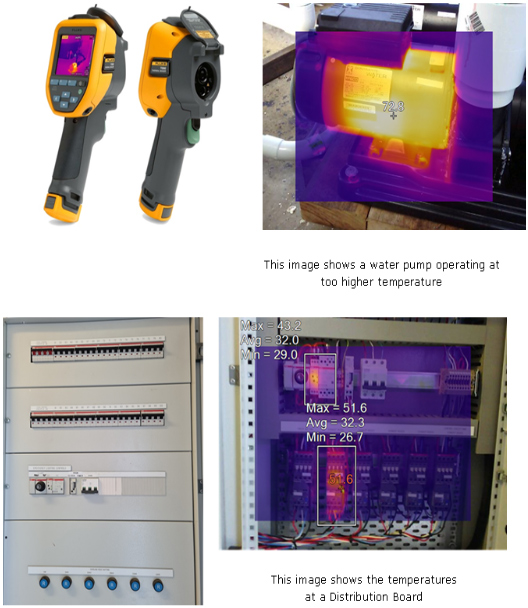

- Overheating Components: Detecting overheating in electrical panels, connections, and equipment, which can prevent potential failures or fires.

- Mechanical Inspections:

Equipment Condition: Monitoring machinery and mechanical systems for temperature irregularities that might indicate wear or malfunction.

Thermal Imaging Benefits:

- Non-Destructive: Thermal imaging doesn’t require direct contact with the object being inspected, allowing for safe and non-intrusive testing.

- Early Detection: It helps identify potential problems before they become serious issues, potentially saving time and money.

- Real-Time Monitoring: Provides instant feedback, which is useful for immediate assessment and decision-making.

- Comprehensive: Captures a wide range of data and can cover large areas quickly.

How It Works:

- Heat Emission: All objects emit infrared radiation based on their temperature.

- Detection: A thermal camera captures this infrared radiation and converts it into an electronic signal.

Image Creation: The signal is processed to create a thermal image (thermogram) where different temperatures are represented by various colors.

David Anderson Electrical has the latest Fluke Thermal Imaging Equipment to perform your required thermal imaging testing in Forster, making sure you have accurate and useful results.