David Anderson Electrical is the number one choice for Power Quality Audits and Analysis in the Forster-Tuncurry region. Our commitment to excellence and our extensive experience set us apart, ensuring that we provide the highest quality service to our clients around Forster and Tuncurry.

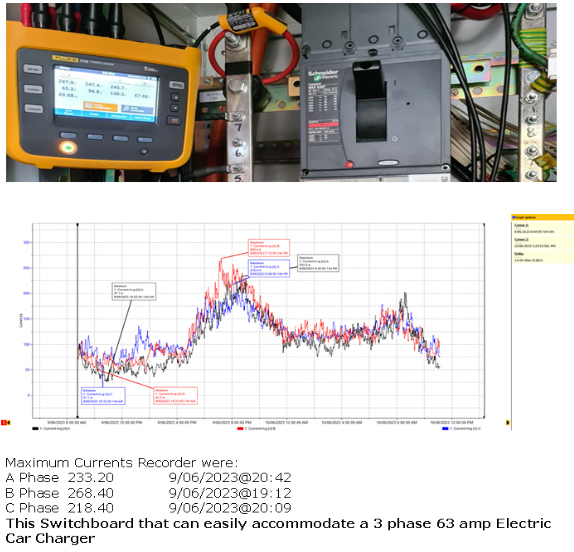

We understand that maintaining optimal power quality is crucial for the efficiency and safety of your electrical systems. That’s why we utilise the latest equipment to perform comprehensive Power Quality Analysis testing. Our advanced tools allow us to accurately measure and analyse various power quality parameters, such as voltage stability, harmonic distortion, and power factor. This precise analysis helps us identify potential issues that could affect the performance of your electrical systems, from minor inefficiencies to significant power disturbances.

Dedication to Power Quality Analysis

We are dedicated to mastering Power Quality Analysis around Forster-Tuncurry and surrounds. Our expertise, combined with our cutting-edge equipment, enables us to deliver detailed insights and effective solutions to your power quality issues. Whether you are a homeowner looking to protect your appliances or a business aiming to enhance your electrical infrastructure’s performance, we have the experience and electrical equipment to provide exceptional results for you.

Power quality analysis involves evaluating the characteristics of electrical power to ensure that it meets the necessary standards for stable and efficient operation of electrical systems. Poor power quality can lead to various issues, including equipment damage, operational inefficiencies, and increased energy costs. Here’s a comprehensive overview of power quality analysis:

Key Aspects of Power Quality:

- Voltage Quality:

- Voltage Sags/Dips: Temporary decreases in voltage, which can disrupt sensitive equipment.

- Voltage Swells: Temporary increases in voltage, which can also affect equipment performance.

- Voltage Fluctuations: Variations in voltage levels over time that can cause flickering lights or other operational issues.

- Frequency Stability:

- Frequency Deviations: Variations in the power frequency (typically 50 or 60 Hz) can affect the performance of synchronous motors and other equipment.

- Harmonics:

- Harmonic Distortion: Distortion in the power waveform caused by nonlinear loads (e.g., computers, LED lights). Harmonics can cause overheating and inefficiencies in electrical systems.

- Power Factor:

- Lagging Power Factor: Occurs when inductive loads (like motors) cause the current to lag behind the voltage, reducing the efficiency of power usage.

- Leading Power Factor: Occurs with capacitive loads, which can also affect system performance.

- Transients:

- Voltage Spikes: Sudden, short bursts of high voltage, often caused by lightning strikes or switching operations, which can damage sensitive equipment.

- Imbalance:

- Phase Imbalance: Uneven distribution of loads across the phases in a three-phase system, leading to inefficiencies and potential damage to equipment.

Tools and Techniques for Power Quality Analysis:

- Power Quality Analysers:Instruments:

- Devices designed to measure various power quality parameters, including voltage, current, harmonics, power factor, and frequency.

- Data Logging: Many analysers can record data over time to analyse trends and diagnose intermittent issues.

- Oscilloscopes:

- Waveform Analysis: Used to visualise and analyse the waveform of the electrical signal to detect disturbances and anomalies.

- Spectrum Analysers:

- Frequency Analysis: Used to analyse the frequency components of the power signal, useful for identifying harmonic distortion.

- Data Acquisition Systems:

- Long-Term Monitoring: Systems that collect and store data over extended periods to analyze long-term quality powertrends.

Benefits of Power Quality Analysis:

- Improved Equipment Reliability: Identifying and addressing power quality issues can prevent damage and extend the lifespan of electrical equipment.

- Operational Efficiency: Ensuring stable power quality leads to more efficient operation of electrical systems and reduces energy waste.

- Reduced Downtime: Proactively managing power quality helps prevent unexpected failures and downtime.

- Cost Savings: Improved power quality can lead to lower energy costs and reduced maintenance expenses.

Steps in Conducting a Power Quality Analysis:

- Identify Objectives: Determine what specific power quality issues need to be addressed.

- Select Tools: Choose appropriate instruments for measuring and analysing the relevant parameters.

- Monitor and Measure: Collect data under different operating conditions to get a comprehensive view of power quality.

- Analyse Data: Review the data to identify any anomalies or deviations from acceptable standards.

- Implement Solutions: Address identified issues through corrective measures, such as installing filters for harmonics or improving power factor correction.

- Continuous Monitoring: Regularly monitor power quality to ensure ongoing stability and performance.

Effective power quality analysis helps ensure that electrical systems operate efficiently, reliably, and safely, minimising potential disruptions and costs.

David Anderson Electrical has 25 years’ experience, in conducting Power Quality Analysis Reports for customers. These reports provide accurate and useful results, to assist Customers understanding the Quality of the Power they are receiving and any effects their Equipment is having on the Electricity supplied to their site.